Die Cutting

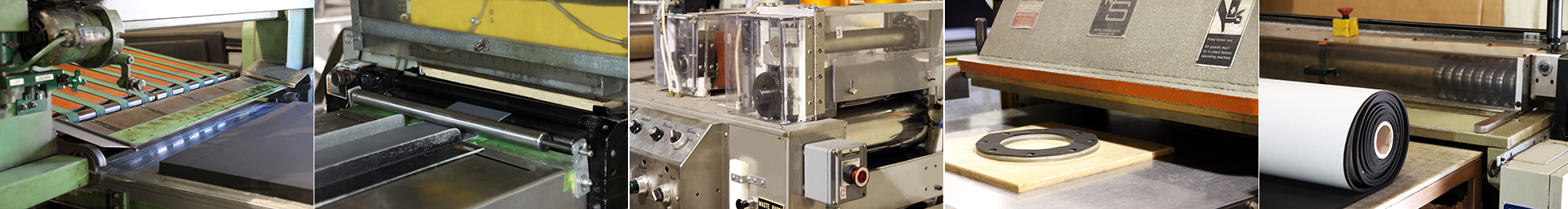

A.J. Rubber & Sponge Ltds. Hamilton, Ontario based gasket manufacturing facility has automated and manual die cutting presses, flatbed presses, rotary cutters and other machinery specifically designed for custom gasket fabrication. Our equipment is capable of efficiently die cutting or stamping out hundreds of small non-metallic parts. We also have rotary die cutting and hole punching capabilities for continuous length strip gaskets. Our rotary and flat bed die-cutting machines allow us to ensure that your parts are produced in a manner that suits your specific requirements.

A.J. Rubber & Sponge Ltd. specializes in the steel rule die cutting of non-metallic gaskets and seals, especially those that are manufactured from foam, rubber and sponge. We are a leading North American provider of advanced gasket die cutting services for a vast array of applications and industries. As custom gasket and seal manufacturers, we proudly maintain a modern manufacturing facility with some of the most advanced die cutting machinery available on the market today. Our precision die cutting capabilities include:

- Kiss cutting

- Flatbed die cutting for gasket fabrication

- Steel rule die cutting

- Rotary die cutting

With extensive experience specializing in the production of precision die cut products such as foam gaskets, rubber gaskets, non-asbestos gaskets, neoprene gaskets, sponge gaskets and many others, our companys reputation for excellence has been built on our commitment to providing superior quality service and precision custom die cut products to our clients for their project requirements. A.J. Rubber & Sponge Ltd. offers a variety of engineering, designing and manufacturing solutions to meet the most demanding of applications. We utilize die cutting presses, steel rule dies and rotary cutting equipment to cut most any non-metallic material, and we can accommodate a wide range of thicknesses for foam, rubber and sponge materials for custom seal and gasket fabrication.

All of our die cut gasket products are manufactured from non-metallic gasket materials that are used in the following industries:

- Medical

- Aerospace

- Military

- Manufacturing

- Automotive

- Packaging

- And many more

We also offer flatbed pressing and laminating services for any material you provide. Alternatively, you may choose a material from our large inventory (which includes both sheet and roll):

- Neoprene

- Rubber

- Vinyl

- Solid rubber

- Crosslinked polyethylene

- SBR (styrene butadiene rubber)

- Urethane foam

- Adhesive backed material

- PVC (polyvinyl chloride)

- EPDM (ethylene propylene diene monomer rubber)

- Polyether foam

- Industrial

- Medical

- EVA (ethylene vinyl acetate)